Kurla West, Mumbai, Maharashtra

- GST NO. : 27AABPT2073R1Z3

Hot Melt Coating Machine

The use of hot melt as a bonding adhesive in the industry has been transformed over the past few years and is gradually replacing conventional solvent or water-based systems and flame lamination.

Trasy Enterprises is one of the leading designers and builder of a wide range of Hot Melt Coating machines. Accuracy & precision coating is assured. Our machines are high quality and are designed specifically for use in the packaging, speciality tapes, upholstery fabric lamination, medical packaging, surgical pouches, Insect sticky traps and other related industries.

Hot Melt Coating process is very similar process to wax coating process. Hot melt adhesives are similar to wax. Hot melt adhesives are of two types:

1. The Thermoset hot melt adhesive.

2. The Pressure Sensitive Adhesive commonly known as PSA.

This coating can be done with various methods. Commonly it was done with reverse roller coating or gravure coating. Gravure coating gives uniform coating but the disadvantage of this coating type is every time you have to change the engraved roller for different grammage of coating. In roller coating the challenge was to achieve thin coating and high speeds. The rotating roll churns the Hot melt and forms bubbles. This results in spotted coating.

In both these processes the molten adhesive is exposed to the air and loses its heat so the hot melt adhesive changes its viscosity and this results in variation of coating thickness. Normally the ends of the coating roll lose heat compared to the centre of the roll hence the coats more grammage at the sides and less at the centre of the web. Sometimes the coating roller gives fumes due to high temperatures of the roller and thin layer of the adhesive on the roller hence the hot melt degrades due to high temperatures and loses its sticking property. So this process has limitation to achieve minimum coating thickness. (not less than 25 gsm.)

Hence, the best method to coat hot melt is through a slot die coating. Advantages of this process are minimum heat loss compared to the other processes. The molten adhesive is never open to air. (Safety factor) Can coat on almost all materials like BOPP, PET, Cloth, HDPE fabric, Felt, Paper, Nonwoven, Aluminium foil, etc.

The coating range in method can be 15 gsm to 600 gsm depending upon requirement. A proper Die and Back up roll setting gives even coating along the width. Also the Proper sync with glue pump and substrate speed and constant melting flow of adhesive, gives even coating along the length. High coating speeds or heavier GSMs can be achieved with the high capacity Melting units. This is to ensure the uninterrupted melt flow while coating.

| Business Type | Manufacturer |

| Country of Origin | India |

| Certification | CE Certified, ISO 9001:2008 |

| Application | Machinery Items |

| Rated Power | 1/4 HP |

| Condition | New |

| Packaging Type | Grey |

| Driven Type | Electric |

| Material | Mild Steel |

| Brand Name | Trasy |

| Warranty | 12 months |

| Size | 85X 35 X30 CM |

| Product Code | AS09 |

| Port | Mumbai |

| Payment Terms | T/T |

| Delivery Time | 30 days |

| Packaging Details | Wooden Box |

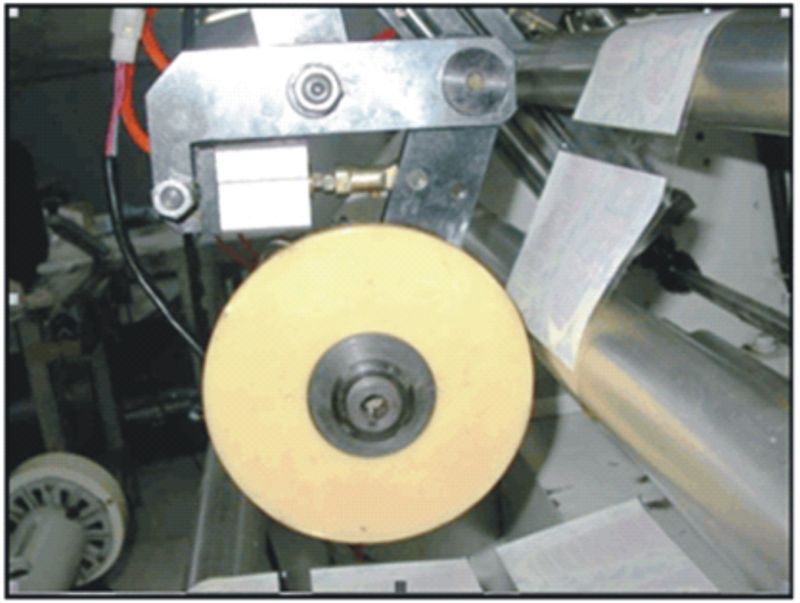

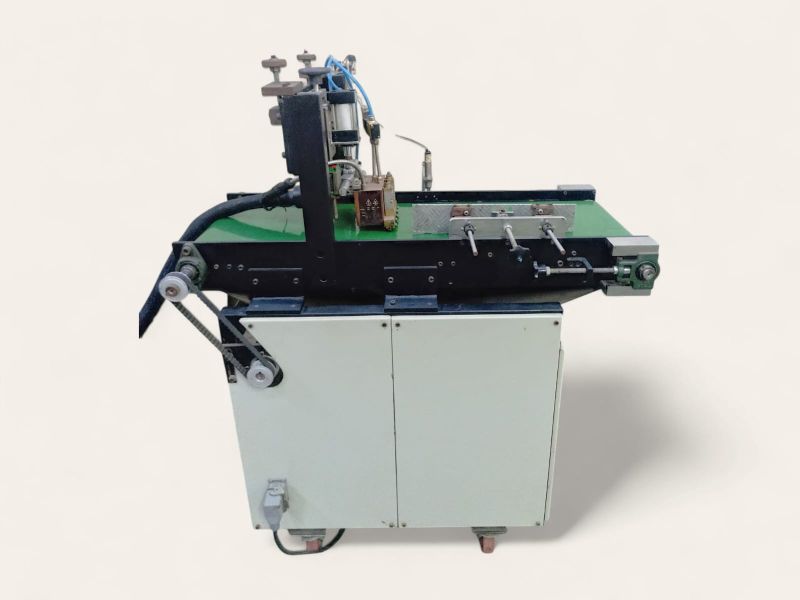

Trasy HMA Disc Applicator for making Anti Slip Heat Shrink Lables.

Trasy HMA Disc Applicator — retrofit glue applicator for shrink-sleeve lines. Apply ultra-thin, controlled EVA adhesive lines (10–15 µm) to the inside of PVC sleeves before seaming — no external heating, no film distortion. Fits existing center/seaming machines; available in single, double, or triple-line configurations.

The concept developed by Trasy Enterprises: — the rotating HMA disc approach (solid EVA-based discs, friction-heated on contact) is well suited for applying a very thin, localized glue line to shrink sleeves without externally heating the film.

Trasy HMA Disc Applicator (attachment for shrink-label center / seaming machines)

Solid EVA hot-melt discs rotate and press against the inner face of the PVC shrink film to deposit 1–3 parallel glue lines (10–15 µm) before center-sealing. No external heating of film; frictional heat softens HMA at the contact point only.

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Electric |

| Condition | New |

| Power | 24 KW |

| Certification | CE Certified |

| Voltage | 440V |

| Machine Weight | 100-1000kg |

| Phase | Three Phase |

| Warranty | 1 Year |

| Country of Origin | India |

| Coating Width | 100-1000mm |

| Coating Weight | 15- 40 g/m2 |

| Coating Speed | 50 m/min Max. |

| Unwind Device | 2 Sets |

| Unwind Diameter | 500 mm |

| Correction Device | 2 Set |

| Rewind Diameter | 500mm |

| Max Temperature | 200℃ |

| Length of Machine | 3400mm |

| Height of Machine | 1850mm |

| Port | Mumbai |

| Payment Terms | T/T |

| Delivery Time | 60 days |

Application Range: Selective Coating, Dot coating, Pattern Coating on Film, Fabric, Textile, Paper & Lamination ...etc.

This coating can be done with various methods. Commonly it was done with reverse roller coating or gravure coating. Gravure coating gives uniform coating but the disadvantage of this coating type is every time you have to change the engraved roller for different grammage of coating. In roller coating the challenge was to achieve thin coating and high speeds. The rotating roll churns the Hot melt and forms bubbles. This results in spotted coating.

In both these processes the molten adhesive is exposed to the air and loses its heat so the hot melt adhesive changes its viscosity and this results in variation of coating thickness. Normally the ends of the coating roll lose heat compared to the centre of the roll hence the coats more grammage at the sides and less at the centre of the web. Sometimes the coating roller gives fumes due to high temperatures of the roller and thin layer of the adhesive on the roller hence the hot melt degrades due to high temperatures and loses its sticking property.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Mild Steel |

| Driven Type | Electric |

| Color | Grey Blue |

| Condition | New |

| Power | 50 Kw |

| Operating Type | Automatic |

| Certification | CE Certified |

| Voltage | 440V |

| Type | High Speed |

| Machine Weight | 2000-3000kg |

| Phase | Three Phase |

| Warranty | 1 Year |

| Country of Origin | India |

| Payment Terms | T/T |

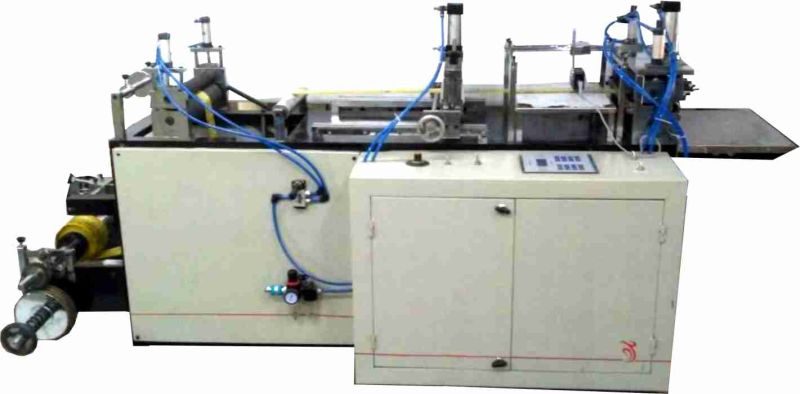

Main features:1. To extend the design of the distance between the second unwinding and the composite makes the edge effect more ideal.Application:RTS hot melt adhesive lamination machine is mainly used in stickers products, such as stickers trademark paper, double-sided tape, foam tape, cloth tape , Kraft paper tape, the US profile paper tape, fiber tape, etc.Technical parameters:Coating width 400-2500mmCoated cloth amount 10-200 g / ㎡Coating speed 80 M / minUnwinding diameter 1000mmWinding diameter 1000mmCorrection device 1setsLength 8400mmHeight 2350mm

| Business Type | Manufacturer, Exporter, Supplier |

| Power | 40 Kw |

| Voltage | 415 V |

| Coating Width | 400-2500mm |

| Coating Weight | 15-200g/m2 |

| Coating Speed | 50m/min |

| Unwinding Dimensions | 1000mm |

| Rewinding Dimensions | 700mm |

| Correction Device | 1 Set |

| Length of Machine | 4800mm |

| Height of Machine | 1350mm |

Main Characteristics :

- An AC converter control is used for both speed and quantity of glue feeding; the speed and glue feeding quantity can be adjusted manually or automatically.

- Adopt intelligent PID temperature control system, the temperature controlled exactly and the error is within 1 Degree Celsius.

- The glue melting tank is coated with the Teflon anti-sticking layer; it can prevent the hot melt adhesive against carbonization efficaciously.

- The precision metric gear pump on the machine can make it steadier to supply the adhesive.

- The high precision of alloy steel spray head can guarantee high quality coating result.

- The high efficiency cooling device insures the applicable range of the basic materials.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Trasy |

| Driven Type | Electric |

| Color | Grey |

| Condition | New |

| Power | 9-12kw |

| Pressure | Medium Pressure |

| Usage | Pesticide Industry |

| Certification | CE Certified |

| Voltage | 440V |

| Capacity | 10-50kg/h |

| Packaging Type | Wooden Base |

| Specialities | High Performance |

| Dimension (LxWxH) | 4m X 3m X 2m |

| Type | Spm Machine |

| Machine Weight | 100-1000kg |

| Phase | Three Phase |

| Warranty | 1 Year |

| Country of Origin | India |

| Corrosion Resistance | Yes |

| Machine Structure | Horizontal |

| Port | Mumbai |

| Payment Terms | T/T |

| Delivery Time | 60 days |

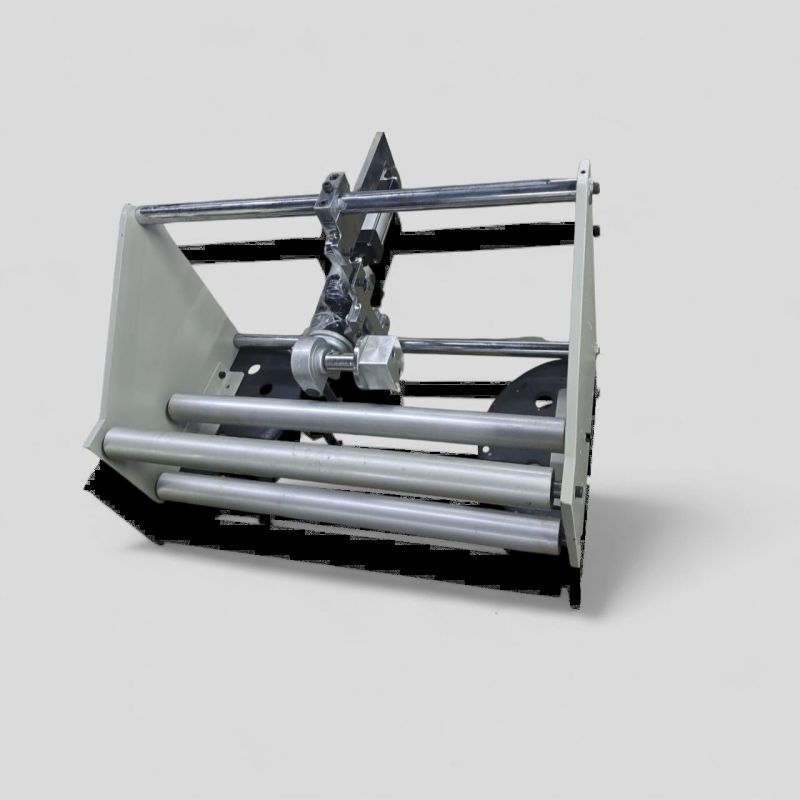

This machine is a hot melt adhesive coating machine. The machine has two heads of slot die coating and two melting units. This enables to coat on both sides of the substrate in a single operation. As a result, it gives double production and less wastage.

This machine is designed especially for making sticky insect traps. It has the capacity to hold 300mm wide rolls and coat up to 300mm wide. Along with double coating heads, it has 3 unwinds and 1 rewind.

Two unwinds hold rolls of the release liner. These liners are coated with slot dies. These slot dies are fed with molten glue by two independent melting units. Both melting units have gear pumps for the controlled, constant and measured flow of glue.

After coating on the release liners, both the papers are laminated with the PVC film sandwiched in between. This PVC film is dispensed from the third unwinder. After the lamination, all the three plies are wound at the winding station.

All the unwinders are equipped with magnetic powder brakes and web guiding systems. The rewind station has a magnetic clutch for a taper tension controlled winding.

| Business Type | Manufacturer, Exporter |

| Brand Name | TRASY |

| Driven Type | Electric, Penaumatic |

| Color | Grey Blue |

| Condition | New |

| Power | 9 HP |

| Warranty | 12 months |

| Country of Origin | India |

| Max. Coating Width | 150mm |

| Unwinding 2 Units | Powder brake |

| Rewind | Tention controlled |

| Port | Nhava-Sheva |

| Payment Terms | T/T |

| Delivery Time | 60 days |

| Packaging Details | Wooden Box |

Hot Melt Coater Specification: Model HMC 6

Machine Type: Die Coating

Max. Size of coating : 150mm, GSM: 20 to 80, Max.

Speed of coating : Speed 15 mpm. Till 40mm tape you can run at 15 mpm. @ 40 GSM.

Bigger sizes or Higher GSM will be proportionally less speed. Eg. 100 mm will run at 10 mpm.

Synchronized coating thickness with speed.

Automatic coating with PLC and Touch Screen.

1. Unwind:2 Stations

To hold 150 mm width of

Silicon paper / Tape Cloth rolls.

76 MM core ID.

Powder Brake

2. Coating Station:

Slot Die coating,

Accurate Temp. Control.

All silicon rolls dynamic balanced.

Back up roller Pneumatically operated.

AC Drive for coating roller.

3. Lamination Nip:

Dynamic balanced Metal roll, Silicone roll

Operation & pressure Pneumatic

AC Drive to the nip

4. Rewind:

To hold max. 150 mm width material.

300 mm Dia. Max.

76 MM core ID.

Taper tension-controlled winding.

AC Drive for controlled winding.

5. Permelter:

Tank capacity 5 Lit.

Melting Capacity 5 Lit/hr

Dry tank capacity: 5 Lit.

liquid tank capacity 0.5 Lit.

Pump Capacity 0.5 Lit/Min

Accurate Temp. Control.

6. Hot melt Hose

To Supply 5 Kgs/hr

Length 2 m

Accurate Temp. Control.

DIMENTIONS: 6’X 4’X 4’

Total Electrical Load: Motors 3 HP + Heaters 6 KW

| Business Type | Manufacturer, Exporter |

| Power | 15 HP |

| Condition | New |

| Color | Grey Blue |

| Driven Type | Electric, Penaumatic |

| Finishing | Powder Coated |

| Brand Name | TRASY,Trasy |

| Size | 2 x 2 x 5 m |

| Warranty | 12 months |

| Country of Origin | India |

| Product Code | HMC 12 2 PC |

| Port | Nhava-Sheva |

| Payment Terms | T/T |

| Delivery Time | 60 days |

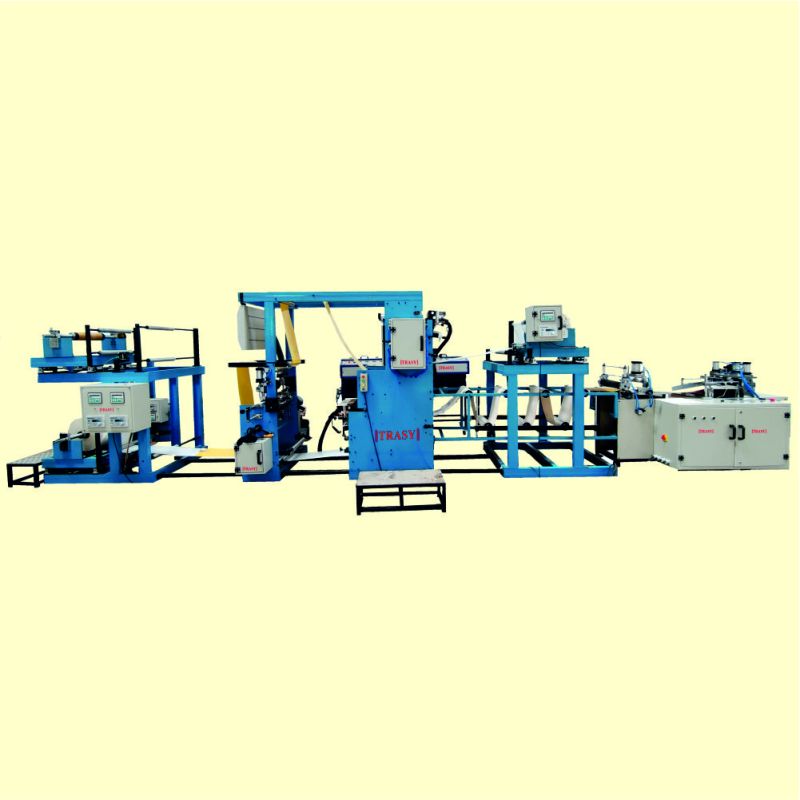

A 300mm width Hot Melt Coating Machine with both side coating and Printing at same time and inline Sheet cutting machine.

INSECT TRAPS MAKING MACHINE:

Machine Specification:

This machine will make rolls of 300 mm (Max.) with 30 gsm hot melt coating.

Process: All processes will be run inline.

- PVC film Printed with Gravure process.

- 2 rolls of Silicon paper of 290 mm will be coated with Hot Melt of 30 gsm.

- And Lamination (transfer of HM on PVC) of Si papers & 0.270mm PVC film.

- Hole Punching, Perforation and Cutting of Si papers laminated to PVC rolls in set of 25(setable) pcs.

Machine Type: Die coating

Max. Size of coating: 300mm, GSM: 15 to 65

Max. Speed of coating : Speed 15 mpm @30gsm

M/c specifications:

- Unwind 1: ( 2Sets)

To hold 310 mm max. width material. (Si Paper)450 mm Dia. Max.

76 MM core ID.

Powder Brake

Web Guide

- Unwind 2:

To hold 300 mm width material. (PVC of 0.27mm)

450 mm Dia. Max.

76 MM core ID.

Powder Brake

Web Guide

- Coating Station: Die coating (2 Sets)

Accurate Temp. Control.

All silicon rolls dynamic balanced.

Back up roller Pneumatically operated

- Lamination Nip:

Dynamic balanced Metal roll & Silicone roll

Operation & pressure Pneumatic

Drive to the nip

- Cutting:

A accumulator provided for the coated material

To punch 1 hole of 5 mm and Perforation line for easy tear.

Pneumatically cut to the set size.

- Permelter: (2 Sets)

Tank capacity 20 Lit.

Melting Capacity 8 Lit/hr

liquid tank capacity 5 Lit.

Pump Capacity 0.4 Lit/Min

Accurate Temp. Control.

Accurate flow control

- Hot melt Hose (2 Sets)

To Supply 0.4 Kgs/hr

Length 2 m

Accurate Temp. Control.

8. DIMENTIONS: 4 m X 2 m X 2 m

9. Total Electrical Load : Motors 7 HP, Heaters 7.5 KW

| Business Type | Manufacturer, Exporter |

| Power | 12 HP |

| Condition | New |

| Color | Grey Blue |

| Driven Type | Electric, Penaumatic |

| Finishing | Powder Coated |

| Brand Name | TRASY |

| Size | 2 x 2x 6 m |

| Warranty | 12 months |

| Country of Origin | India |

| Capacity | Can Make 36000 cards of A4 Size in 8 hrs |

| Product Code | HMC 12 2 P + PC3 |

| Port | Nhava-Sheva |

| Payment Terms | T/T |

| Delivery Time | 60 days |

A 300mm width Hot Melt Coating Machine with both side coating and Printing at same time and Sheet cutting machine.

Hot Melt Coater Specification:

This machine will make rolls of 300 mm (Max.) width & max 600mm dia. with 30 gsm hot melt coating. Process

- Silicon paper of 300 mm will be coated with HM 30 gsm.

- Lamination (transfer of HM on PVC) of Si paper & 0.270mm PVC film.

- Winding of Si paper & PVC roll.

Machine Type: Die coating

Max. Size of coating: 300mm, GSM: 15 to 65 Max. Speed of coating : Speed 10 mpm @30gsm

M/c specifications:

- Unwind 1: ( 2Sets)

To hold 310 mm max. width material. (Si Paper)450 mm Dia. Max.

76 MM core ID.

Powder Brake

Web Guide

- Unwind 2:

To hold 300 mm width material. (PVC of 0.27mm)

450 mm Dia. Max.

76 MM core ID.

Powder Brake

Web Guide

- Coating Station: Die coating.( 2 Sets)

Accurate Temp. Control.

All silicon rolls dynamic balanced.

Back up roller Pneumatically operated

- Lamination Nip:

Dynamic balanced Metal roll & Silicone roll

Operation & pressure Pneumatic

Drive to the nip

- Rewind : for PVC + Si Paper

To hold 310mm max. width material.

600 mm Dia. Max.

76 MM core ID.

Tapper tension controlled winding.

AC Drive for controlled winding.

- Permelter: (2 Sets)

Tank capacity 20 Lit.

Melting Capacity 8 Lit/hr

liquid tank capacity 5 Lit.

Pump Capacity 0.4 Lit/Min

Accurate Temp. Control.

Accurate flow control

- Hot melt Hose (2 Sets)

To Supply 0.4 Kgs/hr

Length 2 m

Accurate Temp. Control.

8. Printing Stations:

Machined & Fabricated from MS Plate.

Heavy construction made, vibration less to suit 10 m/min coating speed.

Idlers of Aluminum seamless pipe by machining.

Rubber rolls pneumatically operated and controlled.

9. DIMENTIONS: 3 m X 2 m X 2 m

Total Electrical Load : Motors 5 HP, Heaters 7.5 KW

WORKING DETAILS OF LABLE MAKING MACHINE:

UNWIND :

Max. 300mm film width with brake.

CUTTING :

Cutting is done by pneumatic knife with very simple procedure of blade setting.

PUNCHING:

Pneumatic punching unit with X/Y axis movement to position the 4 hole position.

DRIVE :

Main drive with PMDC drive with thirstier control for step less speed variation.

PULLING DRIVE :

AC servo motor driven by microprocessor based with pneumatic pinching rollers.

CONTROL PANEL :

Key board for setting length of sheet. All settings & counting numbers are displayed on LCD display. The basic program runs on microprocessor.

COUNTERS:

One integrator total production counter. Display of cuts per minute is also provided.

| Business Type | Manufacturer, Exporter |

| Brand Name | Trasy |

| Color | Grey |

| Condition | New |

| Automatic Grade | Semi Automatic |

| Power | 9-12kw |

| Certification | Iso 9001:2008, Ce Certified |

| Voltage | 440V |

| Weight | 1000-2000kg |

| Country of Origin | India |

| Warrenty | 1 Year |

| Product Code | HMC12 T |

| Port | Mumbai |

| Payment Terms | T/T |

| Delivery Time | 60 days |

| Packaging Details | Wooden Box |

Hot Melt Coater Specification: This machine will make rolls of 300mm (Max.) width & Max 600mm dia. Of 270 micron PVC with hot melt glue and silicon paper. Also can make 100m rolls of 80 micron LDPE coated with hot melt on 3” paper core.

Machine Type: Die coating

Max. Size of coating: 300mm, GSM: 15 to 60 Max. Speed of coating : Speed 0- 15 mpm

M/c specifications:

1. Unwind : (2 Sets)

To hold 310 mm max. width material. 600 mm Dia. Max. 76 MM core ID. Powder Brake Web Guide

2. Coating Station:

Die coating. Accurate Temp. Control. All silicon rolls dynamic balanced. Back up roller Pneumatically operated

3. Lamination Nip:

Dynamic balanced Metal roll & Silicone roll Operation & pressure Pneumatic Drive to the nip

4. Rewind :

To hold 310 mm max. width material. 400 mm Dia. Max. 76 MM core ID. Tapper tension controlled winding. AC Drive for controlled winding. And Turret Winder for LDPE wrap winding.

5. Permelter:

Tank capacity 12 Lit. Melting Capacity 12 Lit/hr liquid tank capacity 6 Lit. Pump Capacity 0.4 Lit/Min Accurate Temp. Control. Accurate flow control

6. Hot melt Hose:

To Supply 0.4 Kgs/hr Length 2 m Accurate Temp. Control.

7. Dimensions:

7 m X 1.5 m X 1.5 m Total Electrical Load : Motors 6 HP, Heaters 5.1 KW

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Electric |

| Color | Grey Blue |

| Condition | New |

| Power | 24 KW |

| Operating Type | Automatic |

| Certification | CE Certified |

| Voltage | 440V |

| Phase | Three Phase |

| Warranty | 1 Year |

| Country of Origin | India |

| Coating Width | 400-2500mm |

| Coated Cloth Amount | 10-200 g / ㎡ |

| Coating Speed | 80 M / min |

| Unwinding Diameter | 1000mm |

| Winding Diameter | 1000mm |

| Correction Device | 1 Sets |

| Length | 8400mm |

| Height | 2350mm |

| Port | Mumbai |

| Payment Terms | T/T |

| Delivery Time | 60 days |

Application Range: Double side tapes; Duct tapes; Double side sponge adhesive tapes; Clean adhesive tapes; Masking adhesive tapes; Alu.foil tapes; Fabric tapes; Shoes material; Medical dressing tapes; Sticker Label; Trademark Label; Film, Fabric, Textile, Paper & Lamination ...etc.Model: RTSCoating width: 100-2500mmCoating weight: 10-200g/m2Coating speed: 5m to 150m/minUnwind device: 2setsUnwind Diameter: 1000mmCorrection device: 2setRewind Diameter: 1000mmMax temperature: 230℃Length of machine: 8400mmHeight of machine: 2350mm

| Business Type | Manufacturer, Exporter |

| Brand Name | Trasy |

| Driven Type | Electric |

| Color | Grey |

| Condition | New |

| Automatic Grade | Semi Automatic |

| Power | 12 HP |

| Application | A 300mm width Hot Melt Coating Machine with Sheet cutting machine and 150mm Hot Melt Coating on LDPE |

| Product Code | HMC RCI 12 + PC3 |

| Port | Mumbai |

| Payment Terms | T/T |

| Delivery Time | 60 days |

Hot Melt Coater Specification: This machine will make rolls of 300mm (Max.) width & Max 600mm dia. Of 270 micron PVC with hot melt glue and silicon paper. Also can make 100m rolls of 80 micron LDPE coated with hot melt on 3” paper core.

Machine Type: Die coating

Max. Size of coating: 300mm, GSM: 15 to 60 Max. Speed of coating : Speed 0- 15 mpm

M/c specifications:

1. Unwind : (2 Sets)

To hold 310 mm max. width material. 600 mm Dia. Max. 76 MM core ID. Powder Brake Web Guide

2. Coating Station:

Die coating. Accurate Temp. Control. All silicon rolls dynamic balanced. Back up roller Pneumatically operated

3. Lamination Nip:

Dynamic balanced Metal roll & Silicone roll Operation & pressure Pneumatic Drive to the nip

4. Rewind :

To hold 310 mm max. width material. 400 mm Dia. Max. 76 MM core ID. Tapper tension controlled winding. AC Drive for controlled winding. And Turret Winder for LDPE wrap winding.

5. Permelter:

Tank capacity 12 Lit. Melting Capacity 12 Lit/hr liquid tank capacity 6 Lit. Pump Capacity 0.4 Lit/Min Accurate Temp. Control. Accurate flow control

6. Hot melt Hose:

To Supply 0.4 Kgs/hr Length 2 m Accurate Temp. Control.

7. Dimensions:

7 m X 1.5 m X 1.5 m Total Electrical Load : Motors 6 HP, Heaters 5.1 KW

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Mild Steel |

| Driven Type | Electric |

| Shape | Rectangular |

| Power | 9-12kw |

| Operating Type | Semi Automatic |

| Certification | CE Certified |

| Voltage | 440V |

| Type | Automatic |

| Machine Weight | 100-1000kg |

| Phase | Three Phase |

| Warranty | 1 Year |

| Weight | 100-1000kg |

| Automatic Grade | Semi Automatic |

| Product Code | HMC-6 |

| Port | Mumbai |

| Payment Terms | T/T |

| Delivery Time | 60 days |

This is the Best Indian machine for coating Hot Melt Adhesive Coating. The machine quality is International level. This Hot Melt Coating Machine is controlled by PLC to assure precision control of coating speed and glue amount. This Hot Melt Coating Machine model has coating weight 15 to 600 gsm. The line speed lowers with increase of GSM.This Hot Melt Coating Machine is used as pilot plant in Hot Melt PSA manufacturing, Narrow web coating and for making Hook Loop self adhesive Tape.

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Electric |

| Color | Grey Blue |

| Operating Type | Automatic |

| Certification | CE Certified |

| Voltage | 440V |

| Machine Weight | 100-1000kg |

| Phase | Three Phase |

| Warranty | 1 Year |

| Country of Origin | China |

| Coating Width | 350mm |

| Coating Weight | 13-80gsm |

| Equality Level | ±0.001mm |

| Max. Working Speed | 150m/min |

| Length of all Roller | 400mm |

| Unwinding Equipment | 2 Set |

| Rewinding Equipment | 1 Set |

| Unwinding Diameter | 600mm |

| Rewinding Diameter | 700mm |

| Correction Edge Device | 2 Sets |

| Glue Melting Speed | 30kg/h (EVA: 3000 centipoise 165℃) |

| Product Code | WHT 350 |

| Payment Terms | T/T |

| Delivery Time | 60 days |

Hot Melt Coating Machine is suitable for making packing tape, paper tape, Adhesive sticker, self-adhesive paper and so on.

WHT350 Hot Melt Coating machine adopts PLC and touch screen to operate and can coat the material up to a width of 350mm. The two laminating rollers can be separated and it is easy to clean and adjust.

The machine adopts two cooling rollers to make sure the material can be protected well from the high temperature

Coating method: rotary rod Coating system without scratch

| Business Type | Manufacturer, Exporter, Supplier |

| Voltage | 415 V 3Phase |

| Inner Diameter | 130mm |

| Pressure Plate Stroke | 300mm |

| Melting Speed | 5 Kg/hr |

| Use Viscosity | within 40000cps |

| Product Code | TE PUR 2.5 |

| Port | Mumbai |

| Payment Terms | T/T |

| Delivery Time | 60 days |

| Packaging Details | Wooden Box, Net Weight : 85 Kgs. |

Technical parameters of PUR host (2.5Kg)

Equipment specifications: 2.5Kg non-stop glue supply machine

Temperature control range: -20℃ --220℃

Standard glue pump type: precision metering gear pump

Standard glue pump capacity: 6cc/revolution

Output : 1 way as standard

Control system: PLC + touch screen + independent temperature control module

| Business Type | Manufacturer |

| Brand Name | Trasy |

| Finishing | Powder Coated |

| Driven Type | Electric, Penaumatic |

| Color | Grey Blue |

| Condition | New |

| Power | 10 HP |

| Product Code | RT5 |

| Port | Mumbai |

| Payment Terms | T/T |

| Delivery Time | 30 days |

| Packaging Details | 1000x650x1200mm |

This machine is designed for making Rat traps on boards with hot melt adhesive.

Board size Min. and Max. 10” max. width and 4” min. width

Coating size 200mm (Max.) X 100mm (Min.)

Max. Machine Speed 3 Pcs/min @ 18 gms per pad

Main Motor 1.0 KW

Max Gluing Width 200 mm

Glue Tank Capacity 5 kg/hr

Machine Size 1000x650x1200mm

Power Requirement 3 Kw, 415 V, 50 HZ, 3 Phase

a) Glue melt tank

1. The shell is made of steel, square steel and 1.2mm steel plate.

2. Use aluminum alloy to build. Two-layer (upper and lower) structure.

3. Adopt high-temperature-resistant high-precision gear glue pump

4. Adopt external precise filter.

5. The glue pump speed is controlled by gear motor

6. Temperature of each layer is controlled by PID system independently

7. Max. temperature is 200℃

8. Melt glue speed: 5 kg/hr (EVA.3000 centipoise 165℃)

9. Heating power: app. 3 KW

b) Hot Hose

1. 2 m length hot melt hose provided.

2. 230V AC, 600 w power.

c) Slot die

1. Coating head: Slot die temperature-resistant alloy steel. SKD210

2. Mounted on Pneumatic piston for up – down moment

3. Coating width adjustment with shims insert

4. Levelling in transfers direction to conveyor is provided.

d) Transmission part

1. Main motor: 1 HP 1 set

2. Glue pump motor: 0.5 HP 1 set

3. Main machine driven by use of belt, chain and gear to transmit.

e) Pneumatic control part

1. Cylinder on slot die, feeding and stopping with head: ¢50mm for each

2. Suitable solenoid valves, flow control and connectors.

f) Electric part

1. Main machine VFD: 1 HP; 1 piece

2. Glue tank VFD: 1 HP; 1 piece

3. Temperature controller: digital PID

4. Heaters: 6KW

5. Touch screen: 3” 1set

6. PLC: 1 set

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Electric |

| Packaging Type | Grey Blue |

| Condition | New |

| Power | 24 KW |

| Certification | CE Certified |

| Country of Origin | India |

| Phase | Three Phase |

| Total Carbohydrate | 1 Year |

| Coating Width | 100-1000mm |

| Coating Weight | 20- 100 g/m2 |

| Coating Speed | 10 m/min max. |

| Unwind Device | 2 Sets |

| Unwind Diameter | 500 mm |

| Correction Device | 2 Set |

| Rewind Diameter | 500mm |

| Max Temperature | 200℃ |

| Length of Machine | 3400mm |

| Height of Machine | 1850mm |

| Port | Mumbai |

| Payment Terms | T/T |

| Delivery Time | 60 days |

In this type of coating procedure, the coating material is measured onto the applicator roller by precision setting of the gap between the upper metering roller and the application roller. The coating is 'wiped' off the application roller by the substrate as it passes around the support roller at the bottom. The diagram illustrates a 3-roll reverse roll coating process.Trasy Enterprises has developed a hot melt coating machine on this principle. The absence of solvents, volatile parts and water, offers an environmentally friendly operating process, and since no additional heating energy is required to evaporate water or solvent and the curing takes place by ambient air temperature or by the humidity of the ambient air, no drying or curing ovens are necessary.Application Range: Tapes, Laminates of Film, Fabric, Textile, Paper...etc.

| Business Type | Manufacturer, Exporter, Supplier |

| Coating Width | 400-2500mm |

| Coating Weight | 10-200g/m2 |

| Coating Speed | 80m/min |

| Unwind Device | 2 Sets |

| Unwind Diameter | 1000mm |

| Correction Device | 2 Set |

| Rewind Diameter | 1000mm |

| Max Temperature | 230℃ |

| Length of Machine | 8400mm |

| Height of Machine | 2350mm |

Main Characteristics :

- Speed (main engine) & quantity (glue) --controlled by PLC.

- Temp. Error (less than 1℃) --Adopt intelligent PID temperature control system

- Teflon Layer(used for sol tank) --Effective to anti-carbonize of the thermosol

- Gear pump (can precision calculate) --To make sure the steady feeding of the adhesive

- Alloy steel spray head(high precision) --To guarantee the high quality of coating result

- Cooling device(high effective) --To ensure the applicable range of basic material

- Second unwind -- to laminate second substrate

- Both unwind adopt EPC to make edge correction

- Unwind fix electric function to load and unload material

| Business Type | Manufacturer, Exporter, Supplier |

| Voltage | 440V |

| Coating Width | 100-1000mm |

| Coating Weight | 15-200g/m2 |

| Coating Speed | 50m/min |

| Unwind Device | 2 Sets |

| Unwind Diameter | 1000mm |

| Correction Device | 2 Set |

| Rewind Diameter | 1000mm |

| Max Temperature | 230℃ |

| Length of Machine | 3400mm |

| Height of Machine | 1850mm |

| Port | Mumbai |

| Payment Terms | T/T |

| Delivery Time | 60 days |

Description :

Trasy Enterprises is one of the leading designers and builder of a wide range of HOT MELT COATING machines with all the options mentioned below. We offer coating machines which are fully featured, efficient and affordable. Accurate & precision coating is assured. Our machines are high quality and are designed specifically for use in the flexible packaging and other related industries. HOT MELT COATING MACHINE by Trasy Enterprises was developed in 2006 & exhibited in IIASE'07 exhibition at Nehru Center, Bombay. Application Range: Double side tapes; Duct tapes; Double side sponge adhesive tapes; Clean adhesive tapes; Masking adhesive tapes; Alu.foil tapes; Fabric tapes; Shoes material; Medical dressing tapes; Sticker Label; Trademark Label; Film, Fabric, Textile, Paper & Lamination ...etc. Model: HMC SLOT DIE COATING Coating width: 100-1000mm Coating weight: 15-200g/m2 Coating speed: 50m/min Unwind device: 2sets Unwind Diameter: 1000mm Correction device: 2set Rewind Diameter: 1000mm Max temperature: 230℃ Length of machine: 3400mm Height of machine: 1850mm

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Cast Iron |

| Power | 5-7kw |

| Certification | CE Certified |

| Voltage | 440V |

| Type | Automatic |

| Phase | Single Phase |

| Warranty | 1 Year |

| Payment Terms | T/T |

Description :

This machine produces the Insect Sticky Traps. These glue traps are also called as pheromone traps as it attracts and traps flying and creeping insects & pests around your plants, fruits and vegetables. It is an effective product that works in the rain, sun or wind that requires no on-going maintenance, has no poison, no chemicals and no vapours or baiting. The Hot Melt Glue Trap is a bright yellow colour plastic sheet and is coated on both the sides with the special glue. This therefore sends out a unique colourful wavelength that attracts a broad range of insects. These may include fruit flies (both male and female), black flies, white flies, shaw-flies, mosquitoes, midges and the day-to-day small flying insects & pests. However, the Blue trap has some important advantages. As well as the blue being more attractive for the thrips; it is also far less attractive to other species. This increases the specificity of the traps and avoids the complications of attracting the non-target and in particular beneficial insects, which need to be preserved. The blue traps can comfortably be used in glasshouses. Here beneficial insects are being released. Some insects are still caught but this is likely to be due to random contact. Even in the most inclement weather it will remain active and useful for around three months. Blue sticky traps are a non toxic way to control and monitor Thrips & Leaf miners. As an integral part of integrated pest management program they can be used in commercial crops, green houses, homes, orchards, flower and vegetable gardens, anywhere insects are a problem. White sticky traps are a non toxic way to control and monitor Thrips, Leaf miners, Shore fly, Tarnished plant bug, European apple sawfly, Fungus, Gnats, Flea beetles. Raspberry beetle. Scale insects, Sciarid Flies, Nuisance flies.

| Business Type | Manufacturer, Exporter |

| Brand Name | TRASY |

| Finishing | Powder Coated |

| Driven Type | Electric, Penaumatic |

| Color | Grey Blue |

| Condition | New |

| Power | 15 HP |

| Country of Origin | India |

| Size | 2 x 2 x 4m |

| Warranty | 12 months |

| Capacity | Can Make 36 K cards of A4 Size in 8 hrs |

| Product Code | HMC 12 2 + PC3 |

| Port | Nhava-Sheva |

| Payment Terms | T/T |

| Delivery Time | 60 days |

A 300mm width Hot Melt Coating Machine with both side coating at same time and Sheet cutting machine

Hot Melt Coater Specification:

This machine will make rolls of 325mm (Max.) width & max 600mm dia. with 30 gsm hot melt coating. Process

- Silicon paper of 300mm will be coated with HM 30 gsm.

- Lamination (transfer of HM on PVC) of Si paper & 0.270mm PVC film.

- Winding of Si paper & PP/PVC roll.

Machine Type: Die coating

Max. Size of coating: 300mm, GSM: 15 to 65 Max. Speed of coating : Speed 10 mpm @30gsm

M/c specifications:

- Unwind 1:

To hold 310 mm max. width material. (Si Paper)450 mm Dia. Max.

76 MM core ID.

Powder Brake

Web Guide

- Unwind 2:

To hold 300 mm width material. (PVC of 0.27mm)

450 mm Dia. Max.

76 MM core ID.

Powder Brake

Web Guide

- Coating Station: Die coating.( 2 Sets)

Accurate Temp. Control.

All silicon rolls dynamic balanced.

Back up roller Pneumatically operated

- Lamination Nip:

Dynamic balanced Metal roll & Silicone roll

Operation & pressure Pneumatic

Drive to the nip

- Rewind : for PVC + Si Paper

To hold 310mm max. width material.

600 mm Dia. Max.

76 MM core ID.

Tapper tension controlled winding.

AC Drive for controlled winding.

- Permelter: (2 Sets)

Tank capacity 20 Lit.

Melting Capacity 8 Lit/hr

liquid tank capacity 5 Lit.

Pump Capacity 0.4 Lit/Min

Accurate Temp. Control.

Accurate flow control

- Hot melt Hose (2 Sets)

To Supply 0.4 Kgs/hr

Length 2 m

Accurate Temp. Control.

8. DIMENTIONS: 3 m X 2 m X 2 m

Total Electrical Load : Motors 5 HP, Heaters 7.5 KW